Non-Destructive testing for concrete:

- Ultrasonic Pulse Velocity (UPV) test

- Rebound Hammer test

- Half-cell potential test

- Concrete Ferro -scanning for Rebar mapping

- Impact-Echo Testing

- Concrete surface resistivity test

01. Ultrasonic Pulse Velocity (UPV) Test:

The UPV test is a valuable tool for assessing the quality and integrity of concrete structures during construction, maintenance, and structural assessment. It can help detect hidden defects, evaluate concrete strength, and aid in quality control and assurance efforts. Concrete quality can be assessed using the Ultrasonic Pulse Velocity (UPV) test, which is a non destructive testing method. The UPV test measures the speed of sound waves as they travel through a concrete specimen. By analyzing the time it takes for sound waves to propagate, it's possible to evaluate the quality, integrity, and potential defects in concrete structures.

Advantages of UPV Testing:

- Non-destructive: It does not harm the concrete structure.

- Rapid: Results are obtained quickly.

- Quantitative: Provides a numerical value (velocity) for concrete quality assessment.

02. Rebound Hammer Test

The rebound hammer test, also known as the Schmidt hammer test, is a non destructive testing method used to assess the compressive strength of concrete by measuring the rebound of a hammer striking the concrete surface. This test provides a quick and straightforward way to estimate the concrete's strength, but it is generally less accurate than traditional destructive testing methods, such as compression tests of core samples.

Advantages of Rebound Hammer Test:

- Non-destructive: It does not damage the concrete structure.

- Quick and easy: Results can be obtained rapidly.

- Portable: The rebound hammer is a handheld device that is easy to transport to various test locations.

03. Half-cell Potential Test:

The half-cell potential test, also known as the corrosion potential or corrosion potential mapping test, is a non-destructive method used to assess the likelihood of corrosion in reinforced concrete (RC) structures. It helps identify areas of potential corrosion within the concrete by measuring the electrical potential of the reinforcing steel relative to a reference electrode.

Advantages of Half-Cell Potential Test:

- Non-destructive: It does not damage the concrete or require invasive testing.

- Rapid: Results can be obtained relatively quickly, allowing for timely assessments.

- Provides spatial information: Helps identify areas at risk of corrosion for targeted maintenance.

04. Concrete Ferro scanning for Rebar mapping

Concrete ferro-scanning, also known as rebar mapping or reinforcement scanning, is a non- destructive testing method used to locate and map the position of reinforcement bars (rebars) or other ferrous objects within a concrete structure. This technique is commonly used in construction, inspection, and structural assessment to ensure the accurate placement and

condition of reinforcement.

Advantages of Concrete Ferro-Scanning for Rebar Mapping:

- Non-destructive: It does not damage the concrete or require invasive testing.

- Rapid: Results can be obtained quickly, allowing for timely assessments during construction or inspections.

- Provides spatial information: Helps accurately locate rebars and determine their depth within the concrete.

Limitations:

- Limited to ferrous materials: Ferro-scanning is primarily used for detecting ferrous reinforcement, so it may not detect non-ferrous materials like fiberglass or composite rebars.

- Limited to surface detection: It provides information about rebars located near the surface and may not detect reinforcement at greater depths.

- Accuracy: The accuracy of the technique depends on several factors, including concrete cover, bar size, and sensor quality.

05. Impact-Echo Testing

Impact Echo testing is a non-destructive testing (NDT) method used to assess the condition of concrete structures, particularly to detect delaminations, voids, and other defects within the concrete. This technique relies on the principle of stress wave propagation and reflection within the concrete to identify areas of concern.

Advantages of Impact-Echo Testing:

- Impact Echo testing is non-destructive, meaning it does not harm the concrete or the structure being tested.

- It can be used on a variety of concrete structures, including buildings, bridges, tunnels, dams, and more

- Impact Echo testing is effective at detecting internal defects within concrete, such as delamination, voids, cracks, honeycombing, and thickness variations.

- The technique provides quantitative data, including the depth and size of defects and the thickness of concrete.

- The testing process is relatively quick, making it efficient for evaluating large areas or structures within a reasonable timeframe.

06. Concrete Surface Resistivity Test:

Concrete surface resistivity testing is a non-destructive test method used to assess the electrical resistivity or conductivity of the surface layer of concrete. This test provides valuable information about the quality, durability, and potential corrosion risk of the concrete.

Advantages of Concrete Surface Resistivity Testing:

- This testing method is non-destructive, meaning it does not damage the concrete or require core samples.

- Surface resistivity tests are relatively quick and straightforward to conduct, making them suitable for both field and laboratory use.

- Surface resistivity values can help predict the risk of corrosion of embedded reinforcing steel in concrete, which is crucial for assessing the durability of structures in aggressive environments.

- It can be used during construction and quality control processes to ensure that the concrete meets specified standards and durability requirements.

- Surface resistivity testing provides in-situ data about the concrete surface layer, allowing for a more accurate assessment of the condition and quality of existing structures.

- By periodically conducting surface resistivity tests on existing structures, changes in the concrete's electrical properties can be detected early, enabling preventive maintenance.

- It allows for the comparison of different concrete mixes, repair materials, or surface treatments in terms of their electrical properties.

Non-destructive testing (NDT) for metal components

Non-destructive testing (NDT) methods for inspecting metal components are crucial for assessing the integrity and quality of metal structures without causing any damage. These methods are widely used in various industries, including aerospace, automotive, construction, and manufacturing.

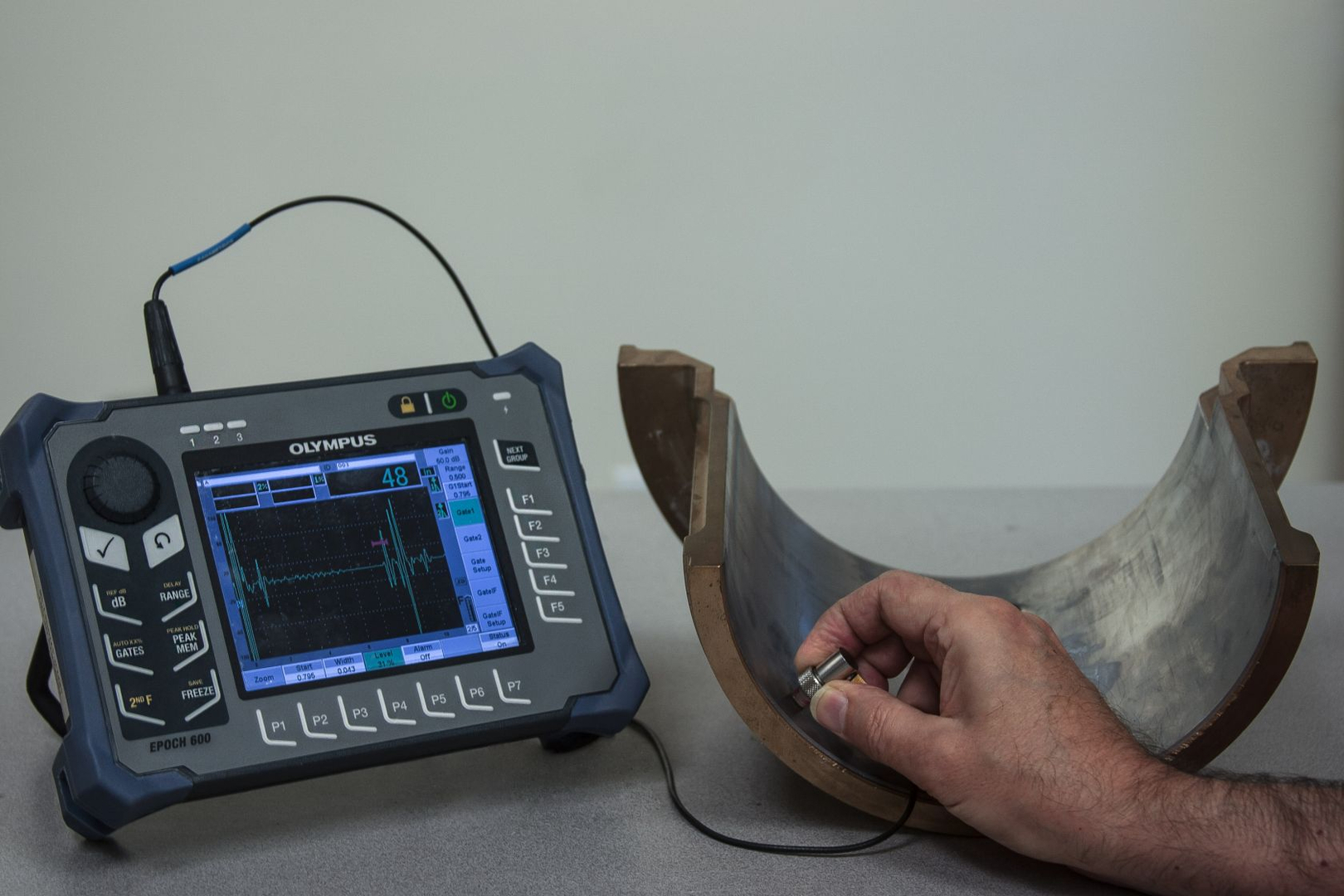

01. Ultrasonic Testing (UT)

Ultrasonic waves are introduced into the metal, and the echoes of these waves are used to detect internal flaws like cracks, voids, inclusions, and thickness variations.

UT is versatile and can be used for various metals, including steel, aluminum, and titanium.

02. Magnetic Particle Testing (MT):

MT is used to detect surface and near-surface defects in ferrous metals.

Magnetic particles are applied to the surface, and the presence of defects causes the particles to align and become visible.

03. Dye Penetrant Testing (PT)

PT is used to identify surface cracks, porosity, and other defects in metals.

A penetrant dye is applied to the surface, and after a specified time, excess dye is removed. A

developer is then applied, which draws the dye out of any defects.